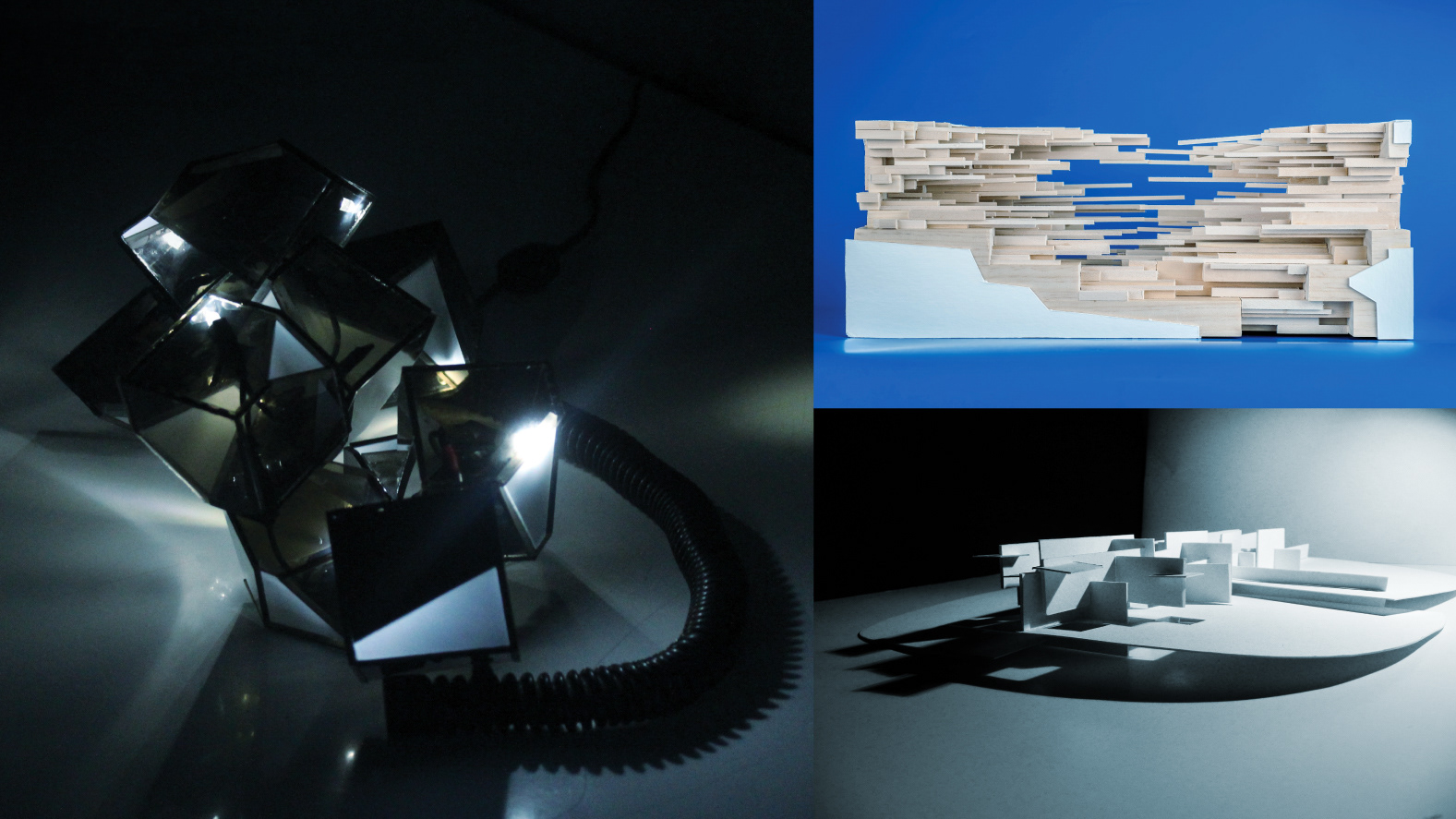

Radiography

Personal Role: Designed the wall pattern, and scripted the brick array to rotate using an image sampler. | Created the image to be used in the image sampler. | Designed, and helped build the brick feeder. | Programmed the Kuka arm to lay the bricks in six tiers. | Assisted the building, and fixing of the wall.

Medium: Rhinoceros | Grasshopper | Kuka PRC | CNC Milling (Feeder, and Gripper)

Main Challenges: 1. Writing, an image sampler script for a point array. | 2. Getting the brick's lists in the correct order (also including the placeholder bricks on each side). | 3. Programming the robot to not hit any of the surrounding objects. | 4. Figuring a way to feed bricks to the robot without being inside the arm's perimeter. | 5. Structurally consolidating the wall.

Unraveling: 1. A lot of tutorial searches, trial, error, and experimenting with Grasshopper's "Sets" components. | 2. Flipping the matrix did not solve the problem of the list organizing each brick's centroid by columns instead of rows. Thus, a series of culling, and mergers re-wrote the list order correctly (including the order of the placeholder bricks). | 3. Modelling the environment, and setting physical guidelines to compare it with the 3D helped solve the calibration issues. | 4. A slide composed of rollers, and wire rails (to hold with slight friction the bricks in queue) was designed. | 5. Rotation of the bricks had to be limited to ensure continuity for a cement-like mixture to percolate within the bricks.

Group: José J. Sosa | Danny Griffin, Yuncao Zhao, Andres Erazo

______________________________________________________________________________________________________________________________________________

The design and fabrication was made possible by parametric programming using Grasshopper and the KUKA PRC plugin. The mechanics for rotating the array of bricks is arranged by an image sampling component. Each unit rotates on its centerpoint depending on the grayscale percentage of the map’s coordinate that is correspondent to the brick.

Dual Wave's design script | Click here for the script's evolution

Stacking the bricks on tiers of 4 rows each, enables the grout’s curing process to be at optimal strength and provide stability for the next rows. Thus, the process spans for about 5 to 6 days in the raw making.

Music by: Topher Mohr and Alex Elena

Structurally binding this stack of bricks is achieved by mixing grout, water, a chemical binder, and metal fibers until it has the consistency of a milkshake. The mixture is then poured in the brick’s openings where metal rods have been placed before. Hence the importance of vertical continuity between the bricks.

Images by: Andrés Erazo

Things to be resolved in the future: Grout draining through small openings due to rotation offset. | Brick imperfections and its accumulated error causing level deformations.